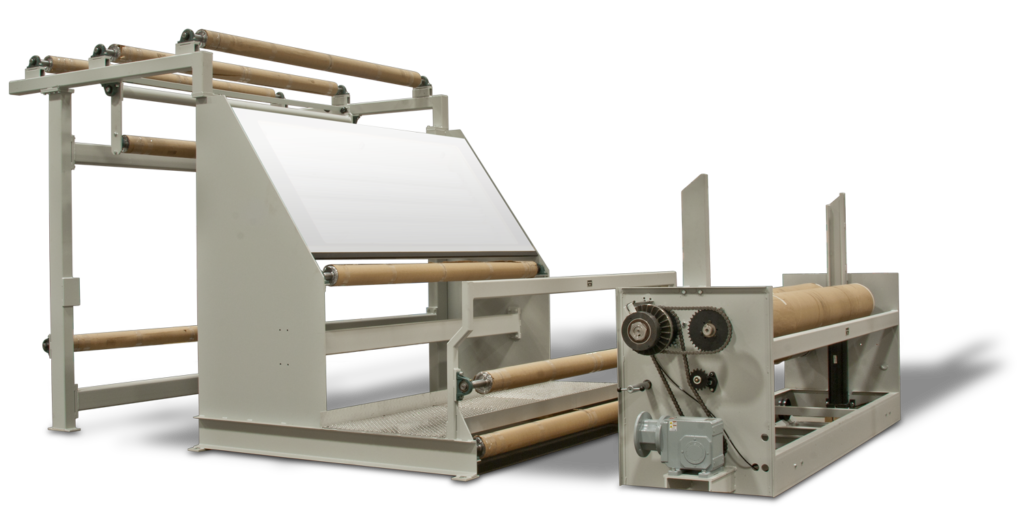

Inspection Machine

- Home /

- Inspection Machine

Problem:

Locating defects in fabrics while winding a consistent package

Solution:

Menzel Inspection Machine

When you ship a roll of fabric, you need to have the confidence that the fabric is of the highest quality, without sacrificing the quality of the roll or the speed in which it can be wound. With the Menzel Inspection Machine you win all the way around.

When it comes to adaptability, this machine will accommodate literally any type or brand of winding system. Whether your inspection requirements include the most delicate knits or the heaviest canvas, Menzel can design and build an inspection machine and drive system to handle your needs.

Standard Features:

Standard inspection machines are available with surface, center and A-frame infeed and winding systems.

Optional Features:

Copyright © 2024 Menzel Machinery USA | Powered by Specia WordPress Theme