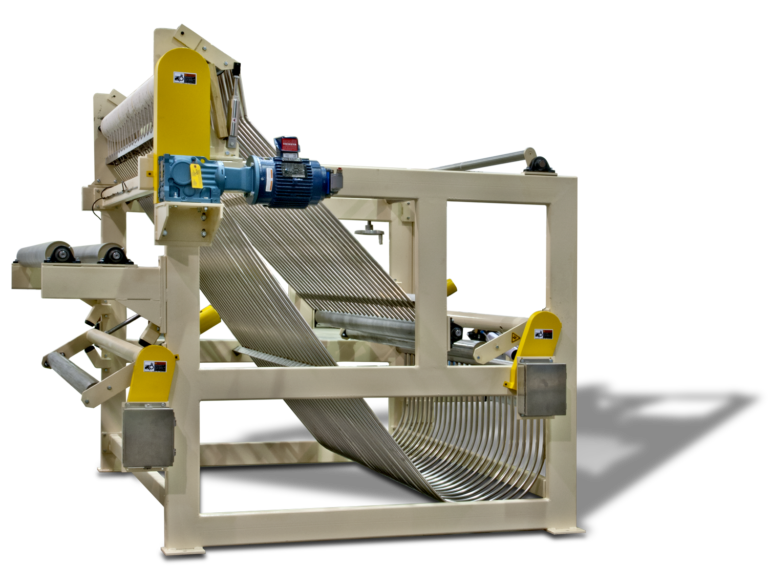

Scrays

- Home /

- Scrays

Problem:

Accumulating fabric to allow continuous range operation during roll changes

Solution:

Menzel Scrays

When your finishing range has to be stopped in order to change roll, production comes to a halt. To avoid this problem, Menzel has developed a line of scrays, in several configurations, to allow continuous operation during roll changes for a wide variety of webs and applications.

Whether you need a J-Scray for a wide variety of fabrics, a U-Scray for delicate fabrics, or a Z-Scray for maximum accumulation, or your requirements call for a custom-designed scray, we have a solution for you.

Standard Features:

Optional Features:

Copyright © 2025 Menzel Machinery USA | Powered by Specia WordPress Theme